Our materials are sustainable and durable to use, but everything comes to an end. So the question arises: What happens to our products when they are no longer needed and end up in the waste stream?

Visionary look ahead

HUESKER is a manufacturer of products made from recycled raw materials. These products are known as our "Eco" range. As we are known as a manufacturer of high-quality products, we do not want to compromise on quality with this sustainable product range. This means that our products meet the same quality requirements as if they were made from original or new raw materials. This puts us at the forefront of the world of sustainable geotextiles, but we're not there yet.

Not all waste is the same

Waste management techniques in the Netherlands are changing rapidly. Separation techniques are getting better and better, but recovering and reusing used geotextiles is complex and time-consuming. We at HUESKER have therefore set ourselves the goal of taking this process into our own hands and optimizing it in cooperation with our partners in the chain in order to create a complete circular economy with our high-quality geotextiles. In this process, there is no longer any room for "waste" and nature no longer pays the price. This minimizes the consumption of natural resources and prevents valuable raw materials from ending up in landfills or incinerators, or worse – being disposed of in our precious natural environment.

Thinking about tomorrow now

The lifespan of our geotextiles is very long – thanks to their high strength and durability, the materials can be used for around 100 years. But at some point, even this time must come to an end. HUESKER is thinking about the future, and we want the disposal phase (dismantling - transport - waste treatment - disposal) to be as sustainable as possible.

Giving back to the Country: taking back dismantled geotextiles

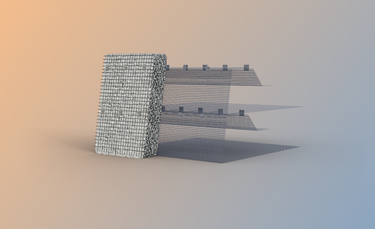

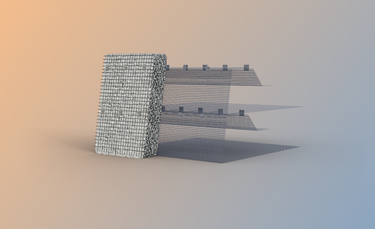

As a leading manufacturer, we have taken the first step and expanded our services to include the take-back of used geotextiles. Currently, in most cases, technical textiles are thermally disposed of and, with a high calorific value, are very well suited as secondary fuels. However, since the textiles are high-quality raw materials such as PP, PET or PVA, whose hardness, durability and rigidity are particularly noteworthy, we want to return these materials to the circular economy. For this purpose, we have developed a disposal concept and are now working together with a recycling company. We have agreed that our geosynthetics, which are made of woven PP, will be transported to the disposal company. In doing so, we ensure that our materials are correctly processed, separated and cleaned. In this way, these are processed into high-quality raw materials and new products (e.g. waste bins) can see the light of day on the basis of these raw materials. We see this waste as new raw materials that opens up countless new possibilities. The take-back and recycling of developed geotextiles is an important step towards conserving and protecting our world's resources in the long term!

All beginnings are difficult

We are still at the beginning and it is difficult to find partners who recognize their responsibility and are willing to choose the recycling service. We need more waste material from the take-back of geotextiles. Our challenge is to optimize this process. To achieve this, the incentive for each party depends heavily on the amount of material to be processed. Our challenge is to retrieve as much acceptable geotextile material as possible to support and improve this development process.

We are on the right track

I'm glad that this concept seems to be (or may become) the jewel in the crown in the geotextile industry. We will certainly reach a point where, on the one hand, the availability of new raw materials (especially oil-based) becomes a real challenge, and on the other hand, procurement becomes too expensive in terms of environmental costs. The development of a circular economy will pave the way for a better future in which the raw materials used are extracted from other sources for virgin material.

Yours, Joris