Yarn and fabric waste cycle

Unfortunately, a certain amount of unavoidable waste in the form of yarn and fabric remnants is always generated during the production of textiles on our weaving machines. Although efficient planning and the appropriate machine settings reduce waste, we cannot avoid it completely. To ensure that the waste does not simply end up in landfill, we have taken on the task and responsibility of utilising these remnants or waste in a sensible way. The residues that we cannot utilise are valuable raw materials and can be fed into the circular economy and the reprocessing cycle to save resources.

Rubbish to us - useful and valuable to others

Edge trimmings from produced goods, yarn remnants after bobbin or warp changes, fabric remnants after article changes or during sample production in the laboratory - all this waste is unfortunately unavoidable. However, behind these yarn, fabric and waste cuttings or empty yarn tubes are valuable raw materials such as PET, PVA, PP and aramid. With these high-quality raw materials and high-quality fibres, new products can see the light of day after recycling and reprocessing. We work together with our partners Altex, Barnet Davy and the Haus Hall sheltered workshop.

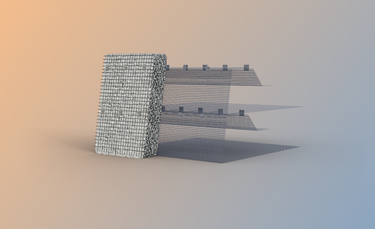

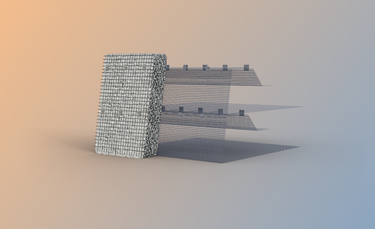

Collecting, separating, sorting, reusing

During ongoing production, the fabric edges are cut off at the Raschelei extraction system, extracted and collected in a reusable container (previously a cardboard box). We pass on our yarn remnants on tubes to the Haus Hall workshop for recycling and separation. The employees remove the yarn remnants from the tubes for us and fill the separated yarn into the mesh boxes. We are able to recycle some of the empty tubes. The yarn remnants are sorted and sent to Altex or Barnet Davy.

A win-win situation

As soon as 44 full pallet cages have been reached, we will organise free collection directly from us or Haus Hall on an alternating basis. For this purpose, we prepare the delivery note including the calculated net weight. As part of the collection of the full goods, 44 empty pallet cages are unloaded by Altex - an efficient deposit system. The textile recycling companies Altexand Barnet Davy process the materials for targeted reintroduction into the market as fleece, which can be recycled as insulation material, for example.

Continuous improvement - ongoing optimisation for greater sustainability

Until a few years ago, the yarn and fabric remnants were still collected in cardboard boxes. These were stored on shelves. As soon as the shelves were full, the boxes were transported by a haulage company to the recycling company, where they were disposed of. It was not only the waste that was problematic, but also the fact that the boxes could not be stacked. There were space problems in the warehouse and the lead times for collections were difficult to plan. Plus HUESKER bore the transport costs. We soon realized that we could do better!

Only advantages for everyone

What initially seemed like a small change turned out to be a big improvement in terms of volume! We save over €15,000 per year in packaging and transport costs. A further advantage: higher efficiency in the rinsing process thanks to the reusable boxes in the extraction systems! A third more filling quantity in the boxes - thus longer running times for the machines and less effort for the machine operators.

I am very happy about this successfully functioning closed-loop system, as everyone involved benefits from it. It has shown that opportunities for improvement need to be seen, addressed and then simply tackled! It was also great to see how the discussions and coordination led to a lot of support and positive feedback!

Reaching the top of the mountain alone is doable, but together as a team it's easier. Many hands, make light work!

Yours, Martin